How Screw Flight Cold Rolling Machine Works

The screw flight cold rolling machine is an innovative piece of equipment designed to manufacture screw flights, which are essential components in various industries, including agriculture, construction, and manufacturing. Understanding how this machine works can provide insights into its efficiency and the quality of the products it produces.

At its core, the screw flight cold rolling machine operates on the principle of cold rolling, a process that shapes metal without the application of heat. This method is advantageous as it preserves the material’s properties, resulting in stronger and more durable screw flights. The machine typically consists of a series of rollers and dies that work together to form the desired shape.

The process begins with a flat strip of metal, usually made of steel or aluminum, which is fed into the machine. As the strip enters, it is guided through a series of rollers that gradually bend and shape the metal into a helical form. The precision of the rollers is crucial, as they determine the thickness and pitch of the screw flight.

Once the metal strip is shaped into a helical form, it is cut to the desired length. The cold rolling process not only shapes the metal but also enhances its surface finish, making it smoother and more resistant to wear and tear. This is particularly important for applications where screw flights are subjected to harsh conditions.

In addition to its efficiency, the screw flight cold rolling machine is known for its ability to produce consistent and high-quality products. The automation of the process reduces human error and increases production speed, making it a valuable asset for manufacturers looking to optimize their operations.

In summary, the screw flight cold rolling machine is a sophisticated tool that utilizes cold rolling technology to produce durable and precise screw flights. Its ability to maintain material integrity while enhancing surface quality makes it an essential machine in various industrial applications.

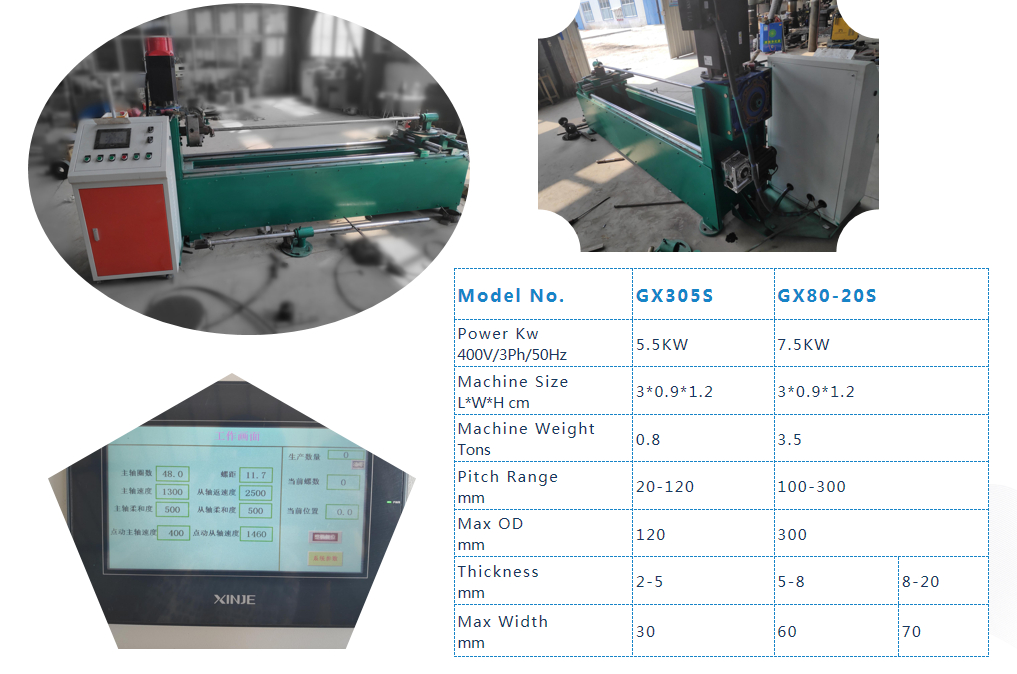

Metal Tape Winding Machine for Screw Flight Production

In the realm of manufacturing, precision and efficiency are paramount, especially when it comes to producing components like screw flights. The metal tape winding machine for screw flight production has emerged as a revolutionary tool that enhances the quality and speed of production processes. This specialized machinery is designed to create screw flights, which are essential components in various industries, including agriculture, construction, and food processing.

The metal tape winding machine operates by utilizing a continuous strip of metal tape, which is wound around a mandrel to form the desired screw flight shape. This method not only ensures uniformity in the dimensions of the screw flights but also significantly reduces material waste. The machine is equipped with advanced technology that allows for precise control over the winding process, enabling manufacturers to produce screw flights with varying diameters and pitches to meet specific application requirements.

One of the key advantages of using a metal tape winding machine for screw flight production is its ability to streamline the manufacturing process. Traditional methods of producing screw flights often involve multiple steps, including cutting, bending, and welding. However, with the metal tape winding machine, these processes are consolidated into a single operation, resulting in faster production times and lower labor costs.

Moreover, the durability and strength of the screw flights produced by this machine are noteworthy. The use of high-quality metal tape ensures that the final product can withstand the rigors of its intended application, providing longevity and reliability. This is particularly important in industries where screw flights are subjected to heavy loads and harsh conditions.

In conclusion, the metal tape winding machine for screw flight production represents a significant advancement in manufacturing technology. By combining efficiency, precision, and durability, this machine not only enhances production capabilities but also contributes to the overall quality of screw flights, making it an invaluable asset for manufacturers in various sectors.

Hydraulic Pressing Machine for Screw Flight Forming

In the realm of manufacturing, the hydraulic pressing machine for screw flight forming has emerged as a pivotal tool for producing high-quality screw flights. This specialized equipment is designed to efficiently shape and form screw flights, which are essential components in various industries, including agriculture, food processing, and material handling.

The hydraulic pressing machine operates on the principle of hydraulic force, utilizing pressurized fluid to generate significant force. This allows for the precise shaping of materials, ensuring that screw flights are formed with accuracy and consistency. The machine is equipped with advanced features that enable operators to adjust parameters such as pressure and speed, catering to different material types and thicknesses.

One of the key advantages of using a hydraulic pressing machine for screw flight forming is its ability to handle a wide range of materials, including steel, aluminum, and other alloys. This versatility makes it an invaluable asset for manufacturers looking to produce screw flights for various applications. Additionally, the hydraulic system minimizes the risk of material deformation, ensuring that the final product meets stringent quality standards.

Moreover, the efficiency of hydraulic pressing machines significantly reduces production time. With the capability to produce multiple screw flights in a single cycle, manufacturers can meet high demand without compromising on quality. This efficiency not only enhances productivity but also contributes to cost savings in the long run.

In conclusion, the hydraulic pressing machine for screw flight forming is an essential piece of equipment in modern manufacturing. Its ability to produce high-quality screw flights with precision and efficiency makes it a preferred choice for industries that rely on these components. As technology continues to advance, we can expect further innovations in hydraulic pressing machines, further enhancing their capabilities and applications in the manufacturing sector.

Post time: Aug-12-2025