Specification

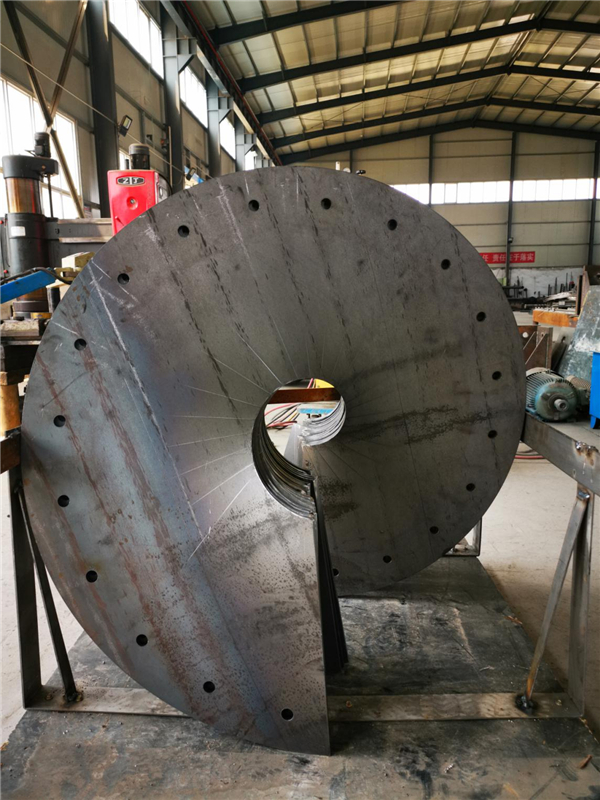

| Max Thickness | 40mm |

| Max OD | 1800 mm |

| Min. ID | 25 mm |

| Pitch Range | 25-1300 mm |

| Max Width | (OD-ID)/2 800mm |

Feature

1. The segmental equal-thickness forming technology is a patented technology developed to solve the difficulty of continuous cold-rolling forming technology in large diameter, large thickness, special specifications and dimensions, and difficult to control wear-resistant materials, stainless steel and other materials.

2. The segmented equal-thickness spiral blades are in the form of single pitch, and the thickness of the outer edge is almost the same as that of the inner hole. After molding, the outer diameter, inner diameter, and pitch can accurately reach the size required by the customer.

3. It can be formed over-large and over-thick, made of low-carbon steel, low-alloy steel, wear-resistant steel, and stainless steel with equal diameter, equal pitch, variable diameter, variable pitch, and inner hole circumference and outer diameter circumference with bosses or gaps Various forms of "segmented equal-thickness spiral blades" are required.

4. Compared with continuous rolling technology, it has good forming accuracy and high qualified rate of finished products, which can meet the requirements of small batches and individualized supply. It is especially suitable for the production of spiral blades of large specifications, large thickness and wear- resistant steel and stainless steel materials.

Case Display